REMOTE ASSET MONITOR (RAM)

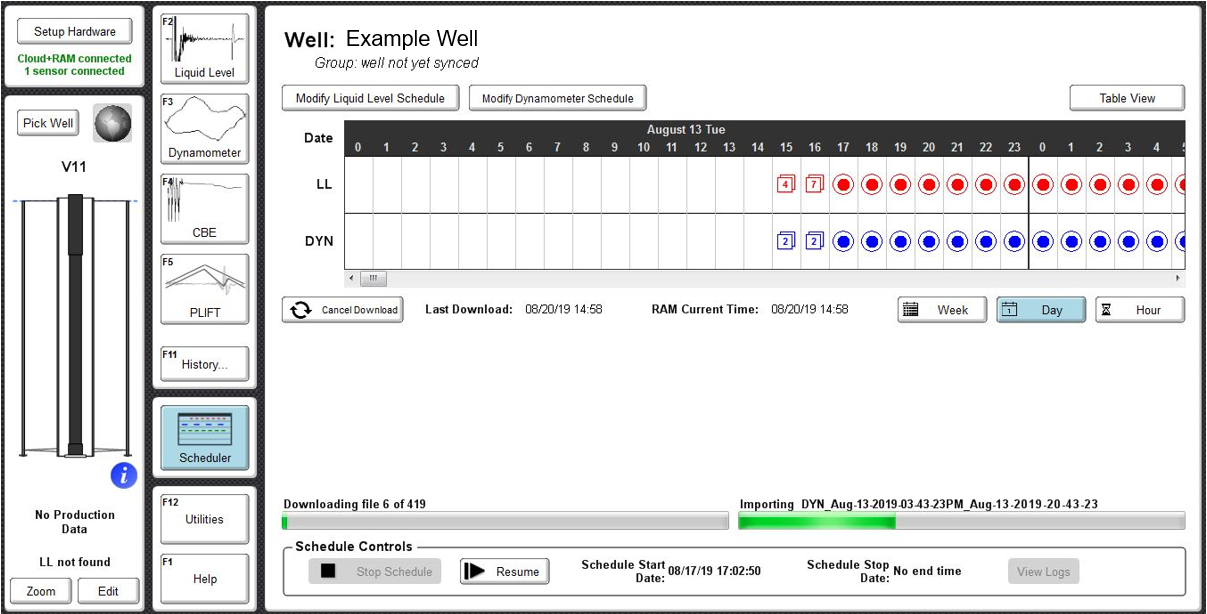

The Remote Asset Monitor (RAM) communicates with the TAM software to remotely acquire liquid level data, acoustic pressure transient data, dynamometer data, and motor power/current data. Operators can schedule time, frequency, and sampling speed to remotely monitor a well for an extended time.

OBJECTIVES

|

|

FEATURES

|

- Monitor individual well performance trends over extended periods of time

- Automatically acquire data without user intervention

- Manual data acquisition override

- Provide remote access to test equipment in the field

- Increase productivity and safety of field personnel

- Reduce operating costs

- Increase productivity and safety of field personnel by reducing travel requirements

- **Pressure Transient scheduling and data acquisition (**Pressure Transient requires a license to acquire data. Pressure Transient is available in TAM 1.9 and later TAM versions. )

|

|

- Portable, lightweight, compact system

- Battery operated

- Powered by AC 110V or solar panel

- Cellular interface

- Connection to remote server via 3G and 4G celluar network

- The RAM system works with TAM 1.8.52 and later TAM versions.

|

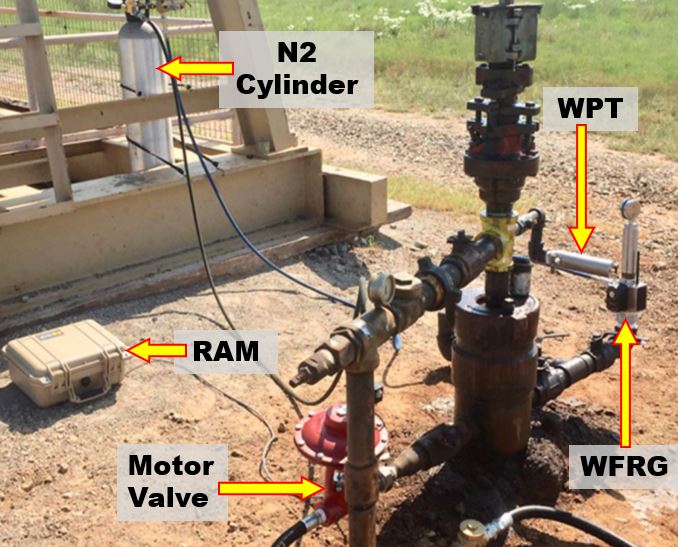

The RAM (Remote Asset Monitor) is the newest addition to Echometer's wireless monitoring tools that include TAM software and sensors designed for real time analysis of well performance. The addition of the RAM to the existing TAM system leverages the capabilities of the current system by allowing the user to remotely acquire and analyze data, and to set up un-attended scheduled acquisitions of dynamometer, fluid levels, pressure, and electrical power/current.

Features include:

1) The ability to acquire data through direct access of the wireless sensor system. The RAM bridges the gap making it seem the laptop were directly connected to the sensors. Once a RAM is deployed, with sensors installed on a well the user can remote-in at any time to directly acquire tests.

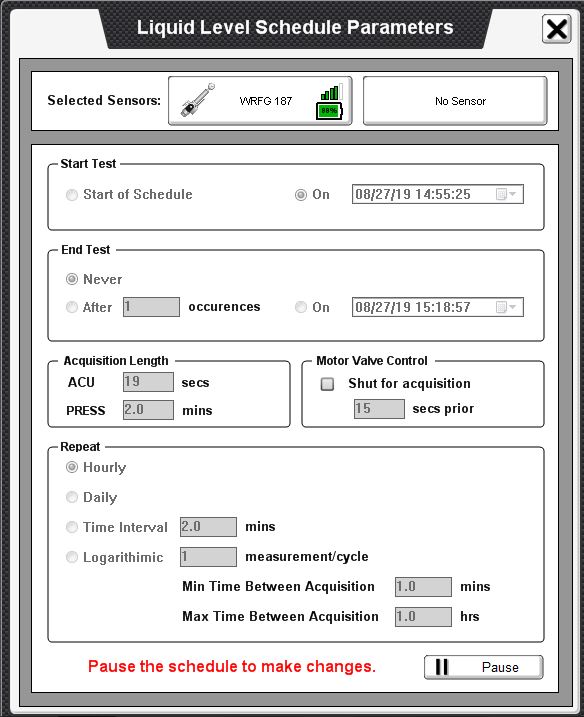

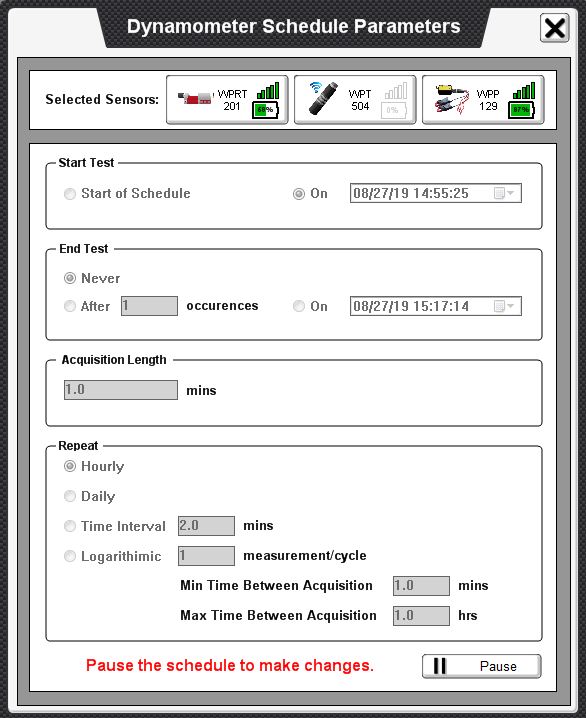

2) The user can set up and modify scheduled acquisitions for dynamometer, liquid level and other tests. Schedule parameters configure the acquisition interval and duration.

3) While a schedule is active on the RAM the user can log in remotely, via cellular connection, or locally through the RAM's hot spot, to retrieve acquired tests and/or modify the acquisition schedule. The remote option eliminates the need to drive to the well.

Click HERE to download the RAM Features and Help Guide.

To request a demonstration of the RAM features and capabilities, please contact: gustavo@echometer.com.

RAM Applications

The RAM system is applicable to all types of production operations.

Rod Pump Wells

- First Delivery Monitoring

- Well Pump Down Tracking

- POC/Timer Set-Up and Evaluation

- Power Analysis

- Pressure Transient Tests (Buildup/Drawdown)

- Fluid Level Depression Tests

Gas Lift Wells

- Start Up Sequence

- Intermittent Monitoring

- Pressure Transient Buildup Tests

ESP Wells

- First Delivery Monitoring

- Pump Down Tracking

- Fluid Level Trends

- Pressure Transient Tests

Gas Wells

- Liquid Loading Trends

- Monitor Batch Treatments

- Pressure Buildup Tests

Plunger Lift Wells

- Plunger Cycle Monitoring

- Liquid Level Monitoring

- Pressure Transient Tests

Flowing Wells

- Flowing Pressure Trends

- Pressure Transient Tests

Injection Wells

- Injection Pressure Trend

- Injectivity Test

- Fall-Off Test